Product Description

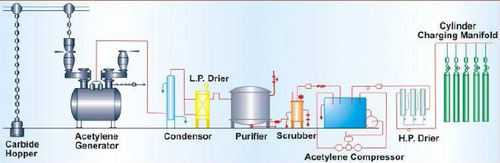

Introduction Acetylene Plant:-

Our Acetylene Plant is highly versatile and designed and manufactured by experienced and qualified Engineers. All the parts are made with the best materials as per drawings with complete inspection and quality control.

The Acetylene plant is highly safe and dependable and is FULLY AUTOMATIC All the operations are automatic and performed by imported pneumatically controlled valves assisted by highly sensitive sensors along with the temperature controlled instruments. The entire plant is designed with utmost safety in mind along with flash back arrestors, High pressure reverse flow check valves and complete help to protect both the equipments and the operators.

The medium pressure Acetylene plants a stationery carbide to water automatic generator. Acetylene is generated as a result of the chemical reaction between calcium carbide and water. The byproduct is calcium hydroxide or lime slurry which is continuously discharged from the generator. The reaction is

Cac2 + 2H2O ---> C2H2 + Ca(OH)2 + 27,000 Calories.

Acetylene is a gas having a garlic odour. When properly proportioned with oxygen and burnt under control as in cutting and welding torches, it provides the highest temperature of any known oxygen gas mixture.

The generator is designed to generate acetylene at a pressure of 7 Psig. Acetylene that has passed through the third stage of the compressor should not be allowed to accumulate in large volumes as acetylene in free state above 15 Psig is highly explosive if ignited. In the operation of the acetylene plant, which has passed the first stage of the compressor is always confined to small volumes within pipes. Acetylene cylinders are so constructed that when charged in accordance with the procedure given in Gas Cylinder Rules 1981, the gas can be stored safely at pressure of 225 Psig. by absorbing the gas in acetone

Acetylene is flammable, when its concentration in air is between 2.5 to 100%. An axiom of the process is ‘keep air out of acetylene and acetylene out of air’. Smoking or naked light within the vicinity of 25 meters of the acetylene plant is absolutely forbidden. Keep all open flames away. Persons entering the plant must remove all matches and lighters from their clothing. They should not wear synthetic clothing. No flash light can be used with complete safety, but the type approved for combustible atmosphere is less likely to constitute a hazard. Lights and Light-fittings should be flameproof type.

Calcium Carbide, CaC2, is a solid rock-like material, a product of the electric furnace. It is supplied in air-tight steel drums and is quite safe to handle when kept dry. Carbide should not be left exposed to the air longer than is absolutely necessary for handling, since it will extract moisture from the air to form acetylene. The contents of the damaged drum must be transferred to air-tight containers or be removed to a safe distance from the plant.

Product Range:-

Technical

Specifications

| 45 M3/Hr.

Acetylene Plant

| 100 M3/Hr.

Acetylene Plant

| 150M3/Hr.

Acetylene Plant

| 200 M3/Hr.

Acetylene Plant

|

Efficiency

| 98%

| 98% | 98% | 98% |

Capacity

| 45 M3/hr. of

Acetylene

| 100 M3/Hr. or

Acetylene

| 150 M3/Hr.of

Acetylene

| 200 M3/Hr.of

Acetylene |

Cylinder Filled per batch

| 60 Cylinders

| 120 Cylinders | 200 Cylinders | 240 Cylinders |

Carbide Size

| 0 ~ 80 mm

| 0 ~ 80 mm | 0 ~ 80 mm | 0 ~ 80 mm |

Salient Features:- - No bulky gas holder required. Automatic controls for feeding water.

- Maintaining temperatures, pressures, and slurry drain are fool proof, efficient and are of international standard.

- Excellent absorption of gas in cylinders. No gas loss and high yield.

- Very simple and safe to operate. Low power consumption.

- Low maintenance cost. Manufactured as per Designs & Drawings Approved by the Chief Controllers of explosives Govt of India.

- Product purity meets world standards

- Special safety features incorporated in the plant

- Stainless Steel Construction

- Decomposer and Melter separately mounted and controlled

- Online moisture meter installed

- Complete laboratory equipment for testing of gas is provided with the plant as standard accessory.

- Double drier provided

- Skid mounted, modular design occupies less space.